Transport rollers – what are they and what are their uses?

Moving very large and heavy loads even over short distances is extremely difficult. To avoid damage to the goods and ensure maximum safety of the entire process, transport rollers. These small and uncomplicated devices not only facilitate transport, but also shorten its time and secure the load. How are they constructed and where are they most often used?

Contents

What are transport rollers?

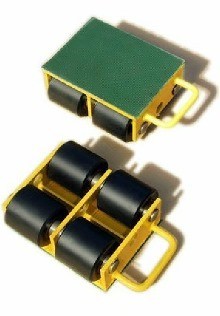

Transport rollers is a special platform with wheels used for transporting machines and other heavy goods, especially those whose weight exceeds the maximum load capacity of forklifts or lifts. Such a platform is attached to a vehicle (e.g. a large forklift), with which the load can be safely and quickly moved to the selected location.

Sometimes you can also come across manual mobile platforms - they are common, e.g. in warehouses or large-format stores. For obvious reasons, however, they are not used to transport heavy machines, and their lifting capacity usually does not exceed several hundred kilograms.

Photo Many of the transport rollers available on the market allow you to transport loads or machines weighing up to several tons.

What are the biggest advantages of transport rollers for machines?

Popularity transport rollers is due to the fact that - due to their simple structure - these devices are failure-free, easy to maintain and rarely subject to mechanical damage.

This type of platform is made in such a way as to withstand very heavy loads without harming the running system. Therefore, operating and servicing costs are very low. If the rollers wear out or come loose, a replacement part can be installed quickly and easily.

Transport rollers they also increase work safety. The surface of the platform is usually covered with rubber, so there is no worry that the machine placed on the chassis will fall or be damaged.

Sometimes transport rollers they are also equipped with a special rotating platform that allows you to freely maneuver the load without having to move the rollers themselves. A reduced profile of transport platforms has also become standard. This allows you to slide it in easily transport rollers under the machine without using physical force.

The use of transport rollers

Transport rollers for heavy loads are devices with very versatile applications. They are commonly used for the internal relocation of heavy machines or objects in production halls from various industries: food, industrial, paper and chemical. Generally - wherever it is necessary to move machines or heavy loads.

Curleasely, materials used for production transport rollers for machines allow them to be used efficiently on various types of surfaces without losing performance. Most of the running system consists of rubberized wheels that do not damage the surface. However, you must remember that such platforms are primarily used for internal transport and are unlikely to be suitable for relocating machines to another hall.

How to choose the best transport rollers?

Before purchasing transport rollers Determine your needs precisely - what type of machines or loads you will transport, as well as their weight, dimensions or packaging method. This will determine what parameters the selected platform should have.

First of all, you need to determine the desired size and load capacity transport rollers for machines, which determine the permissible load of the platform. As a rule, the most available rollers have a load capacity of several tons, but there are also those that allow the movement of a machine weighing more than a dozen or so tons. Remember that the load capacity marking for specific transport rollers gives the maximum load value. Always have one or two spare units and choose rollers with a higher load capacity than your needs require.

Photo One of the most important parameters of transport rollers is their load capacity. Many of these devices allow you to move materials weighing several or even a dozen or so tons.

Of course, the quality and material of workmanship are also important transport roller, just like its construction. It's important to transport rollers:

- were made of a stiff material adapted to the conditions - this is important if the rollers are to be used in halls with a high degree of dust or humidity;

- characterized by low rolling resistance - this will not only enable you to move goods faster and more conveniently, but will also reduce the risk of mechanical damage transport rollers, and thus extend their life;

- they had secured and adjusted bearings to ensure high rolling smoothness and safety of the transported goods;

- all necessary certificates and approvals for industrial use.

Transport roller with such properties guarantees efficient operation, but also significant savings in energy consumption of the machine used for transport. A faulty platform may also overload the machine and contribute to faster wear of its engine components.

Are you wondering which transport rollers are best? contact us! We will offer you a solution that will be 100% tailored to your needs.